Roland 80017A and 5534A Dilemma

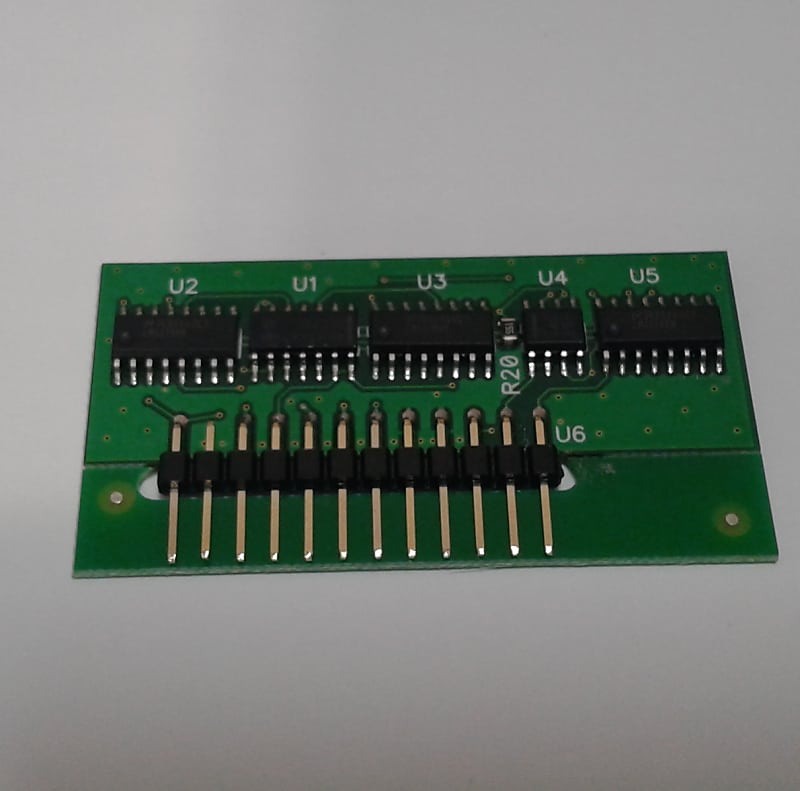

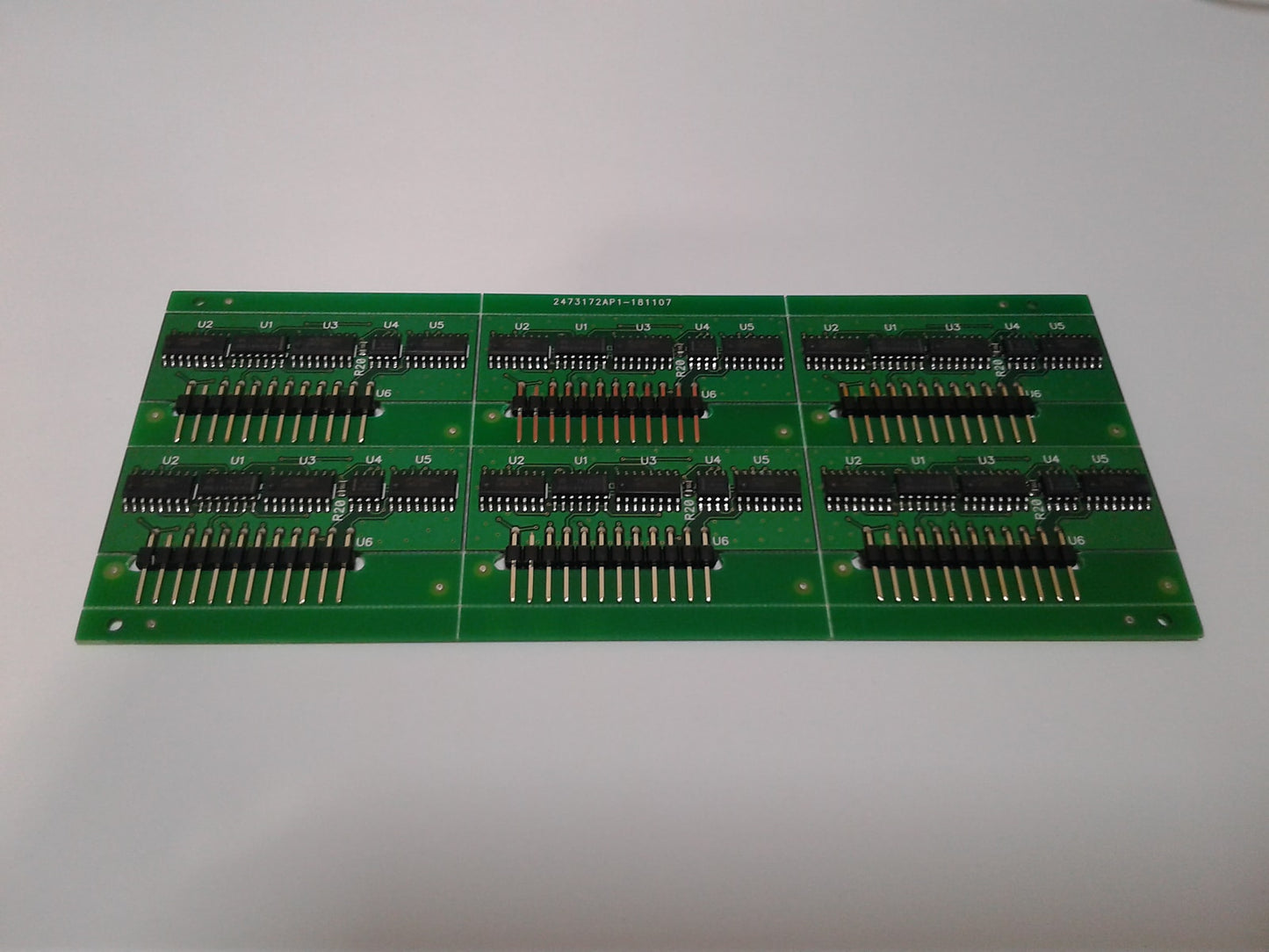

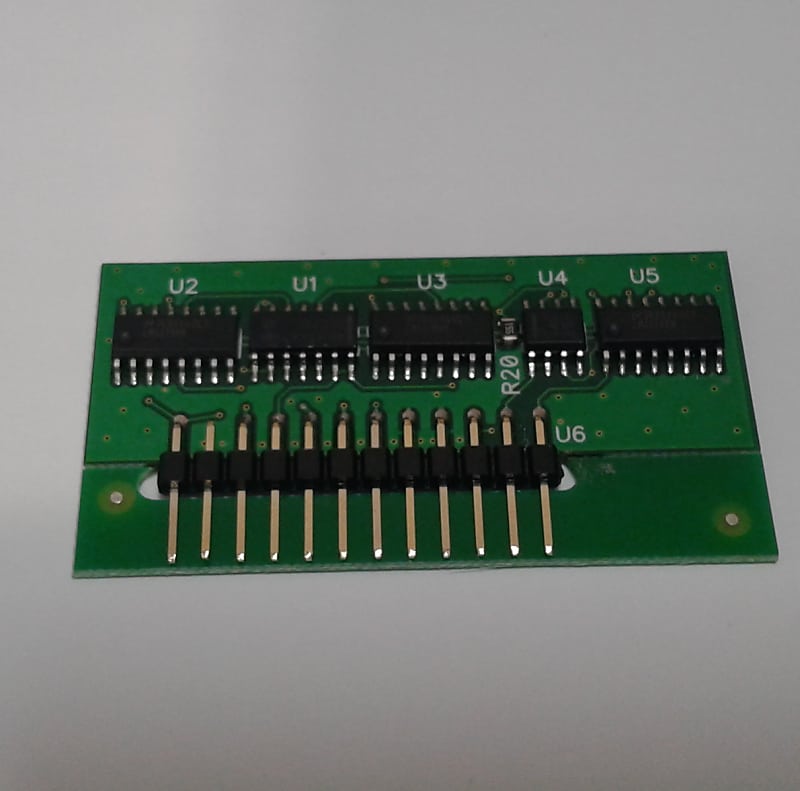

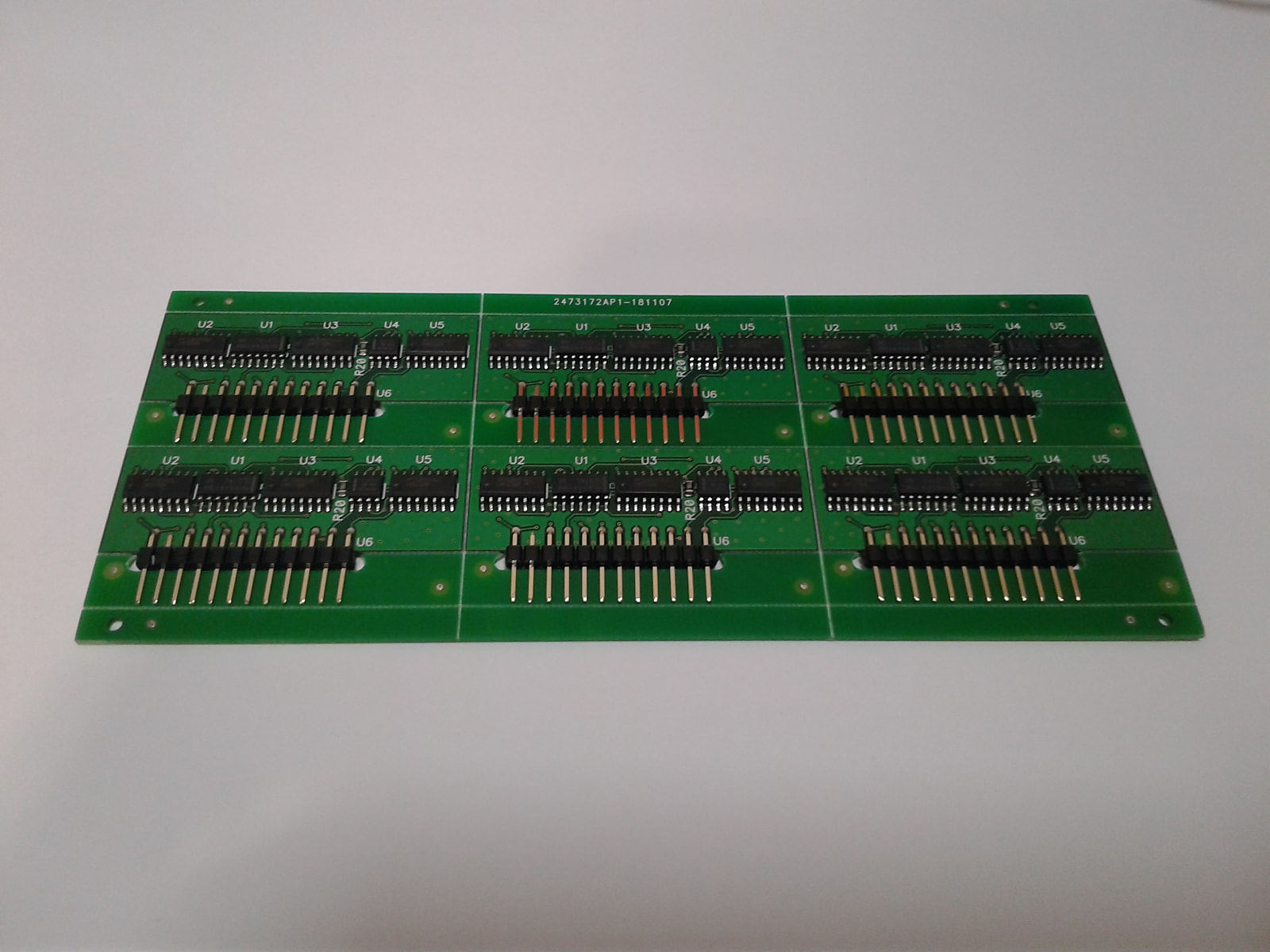

A few times a week, I get a call from somebody shopping around for a technician to repair their Roland Juno 106, Roland MKS-30, Roland HS-60, Roland GR-700, or Roland MKS-7. Generally, the prospective customer wants to know if I’m familiar with X problem, a problem almost always rooted in failing IC’s that are the topic of this article, and how much it will cost to fix it. Unfortunately, this is a difficult question to answer and I’ll elaborate on it in a minute. First off, the self proclaimed experts out there have totally screwed up the service market for these models. Based on my professional opinion, part replacement by a competent technician is the only long term repair option available and the parts alone cost from $150 to $250, not including my labor.. Furthermore, you need special tools to calibrate the synthesizer after any work has been done to it, so this is not really a DIY job. I have a 3 week turn around time. I am no longer providing epoxy stripping services and have my own proprietary line of 80017a ICs. MC5534a ICs are coming soon.

Before I get started with this rant, all of the above listed synths are grouped together because they have common proprietary Roland parts in them, the Roland 80017a VCF/VCA ICs and the Roland MC5534a waveshaper ICs. These proprietary Roland parts suffer from a bunch of very common problems that are worth talking about and, contrary to what you might have heard, there isn’t really a realistic solution to repair them.

The Roland 80017a and MC5534a ICs are odd looking alumina ceramic substrates with electrical parts mounted to them that are sealed in an epoxy coating. These ICs fail because of this epoxy coating interfering with the components mounted to them. About 10? years ago, somebody on the net posted a video with a solution to salvage a 80017a VCF / VCA IC. The solution is to strip the epoxy coating from them, and hey they work again… most of the time. Unfortunately, there are two ways that the epoxy interferes with the substrates and/or components and at least 3 failure modes related to issues created by the epoxy. Stripping the epoxy only solves one failure mode, buys you a bit of time related to the second failure mode, and simply can’t resurrect a damaged component or failed MC5534a. If this isn’t complicated enough already, removing the epoxy removes a heat dissipation conduit for the substrate embedded resistors – effectively making them more prone to thermal induced failure!!

The three failure modes of the 80017a are: stress from the epoxy actually breaking physical connections from component to component on the substrate, the parasitic electrical properties of the epoxy interfering with the electrical values of the components, and downright failure of components due to stress caused by the above two failures. The first problem can sometimes be fixed depending on the break and your interpretation of the time = money equation. Unfortunately, stripping the 80017a can only address the surface issues and epoxy lurking under the ICs, which can’t be removed, can still break the connections. Basically, the epoxy expands and contracts from heat when your synth warms up. The second problem can usually be fixed by simply removing the epoxy, and if you’re unfortunate enough to have an IC with the third problem, you need to buy a new one. Removing the ICs with low quality tools will damage the board that they are mounted on and your synth will not work.

Hey, if you made it this far, good for you. I know of a few companies out there manufacturing new MC5534a and 80017a. Some are better than others. Some shops claim to be specialists in epoxy stripping. In conclusion, and based on my own research, the epoxy stripping method just doesn’t work and you will need to replace the chips eventually.

Borish Electronics

Custom Roland Juno 106 Chip 80017A

Share